螺桿醫生

破壞模式:剝蝕

剝蝕屬於材料接觸疲勞破壞的形式。鋼珠滾動時,軌道次表面之最大剪應力區產生初始裂紋,經由反覆應力作用後裂紋成長至材料表面,材料剝落後呈現坑洞的形貌。

發生主因:

達使用理論壽命、該接觸位置負荷過高。

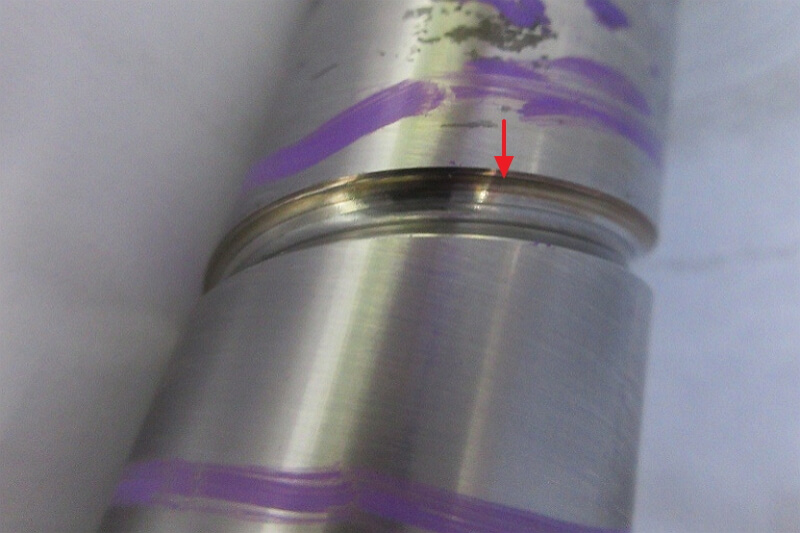

破壞模式:鏽蝕

含水性的液體或處於高溫差、高濕度之環境,水氣導致螺桿產生銹斑,甚至長時間運轉後甚至導致大面積的鏽蝕。

發生主因:

高濕度環境、水溶液入侵、潤滑油脂防護失效。

破壞模式:燒傷

當螺桿受到負荷時,不免產生磨擦力。在潤滑不足的狀況下,摩擦熱無法有效地排除,潤滑劑無法發揮正常功能,導致軌道面過熱呈現黃褐色。

發生主因:

潤滑不良、負荷過重。

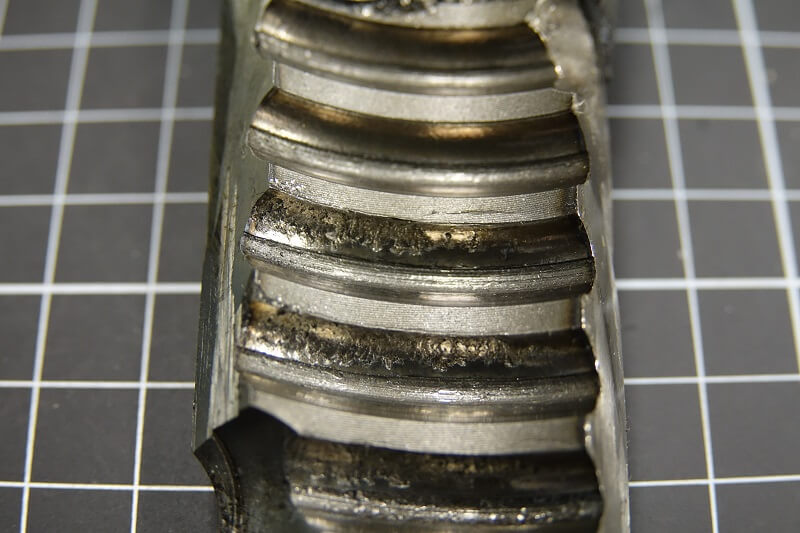

破壞模式:破裂

承受過大的負荷導致鋼珠迴流不順,使得軌道面應力集中與異常磨損,超出材料可承受範圍後,最終導致表面崩裂。

發生主因:

外部衝擊力過大、循環異常。

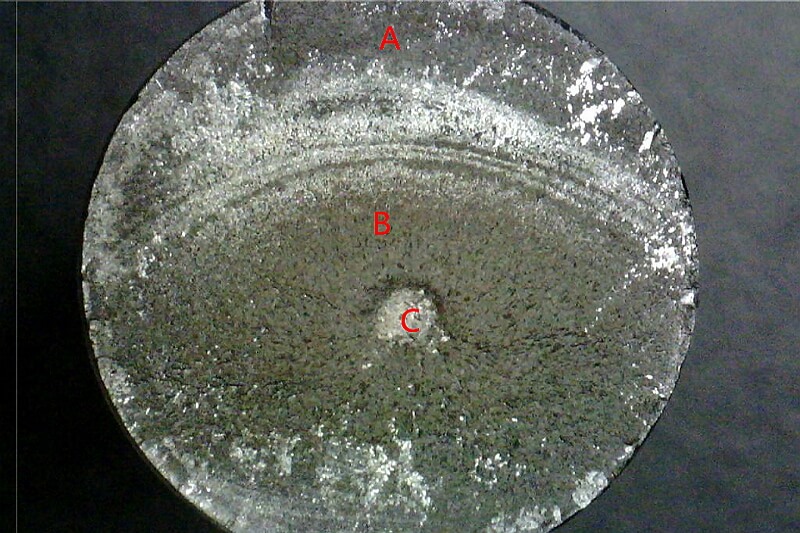

破壞模式:肩部斷裂

運轉時螺桿肩部反覆受到彎曲的力量,使得初始裂紋自A→B→C最終斷裂。

發生主因:

組裝偏擺過大、肩部幾何偏擺過大、肩部強度不足

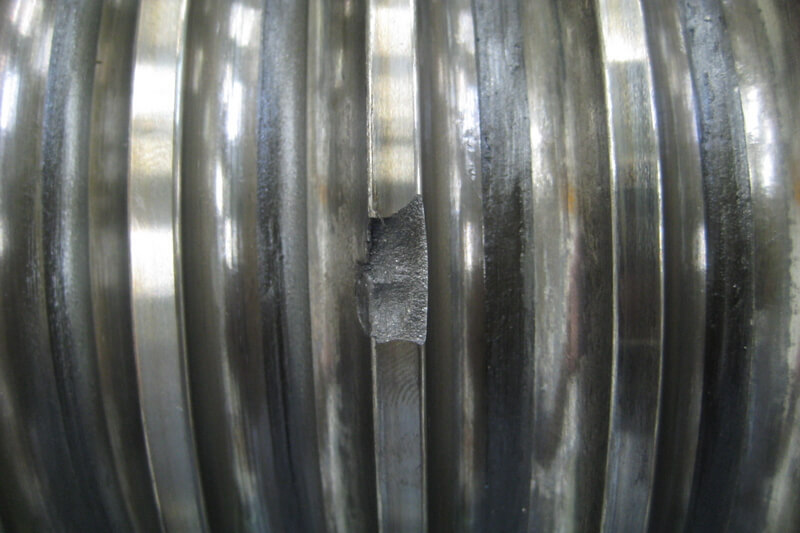

破壞模式:異物入侵

於高粉塵環境中,外在的粉屑無法被有效的隔絕入侵螺帽內部,長時間使用將導致運轉不順,甚至迴流系統阻塞。

發生主因:

粉屑粒徑小於防塵配件之防護能力。

破壞模式:切削液、冷卻液入侵

切削液、冷卻液與潤滑油脂相衝突,導致油脂異常失效與變色。

發生主因:

管路洩漏、防護失效、潤滑油脂變質。